Global trends and unique solutions, digitalization to develop industry and innovations supporting an ecological approach – these and other issues were taken up by renowned experts during the Masters&Robots Industry Edition. This prestigious event took place in the Aula Forum in Polkowice. To celebrate the company’s 60th anniversary KGHM invited innovation leaders to come to the Copper Basin centre. The copper giant emphasizes the importance of innovation for Polish industry, and the importance of Polish industry to create modern technological solutions. For years KGHM Polska Miedź S.A. has analysed and implemented innovative solutions in its activities in copper mining and across the organization. Industry 4.0 and its development are one of the company’s strategic objectives.

Our response to increase in competitiveness in the production and mining sector and Industry 4.0

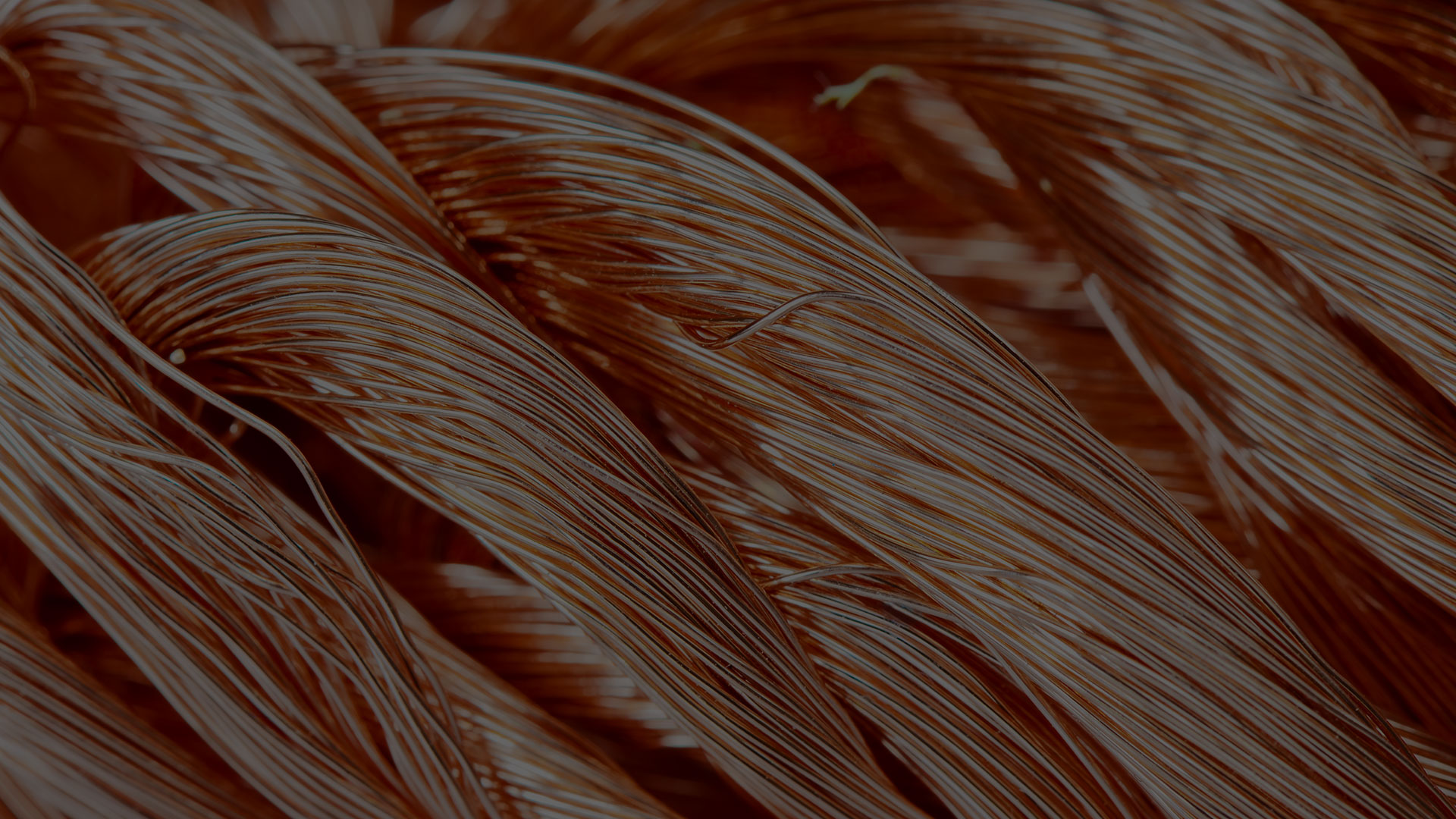

- Carried out investment activities to maintain domestic mining production at the level of 450 thousand tonnes of Cu in ore and the annual average metallurgical production at the level of 540 thousand tonnes, in accordance with the Strategic goals,

- The Revolving-Casting-Refining (RCR) Furnace in the Legnica Copper Smelter and Refinery improved the division’s capacity to process materials purchased from third parties and increased the overall production capacity,

- Energy reviews in all Divisions and the Head Office pointed to new areas for energy savings projects in accordance with the Energy Management System,

- Built skills to develop the power engineering area, including RES (investments in photovoltaic power plants in Legnica Copper Smelter and Refinery, Głogów Copper Smelter and Refinery and the Obora Sandpit),