Summary of the

year 2021

Dear Stakeholders,

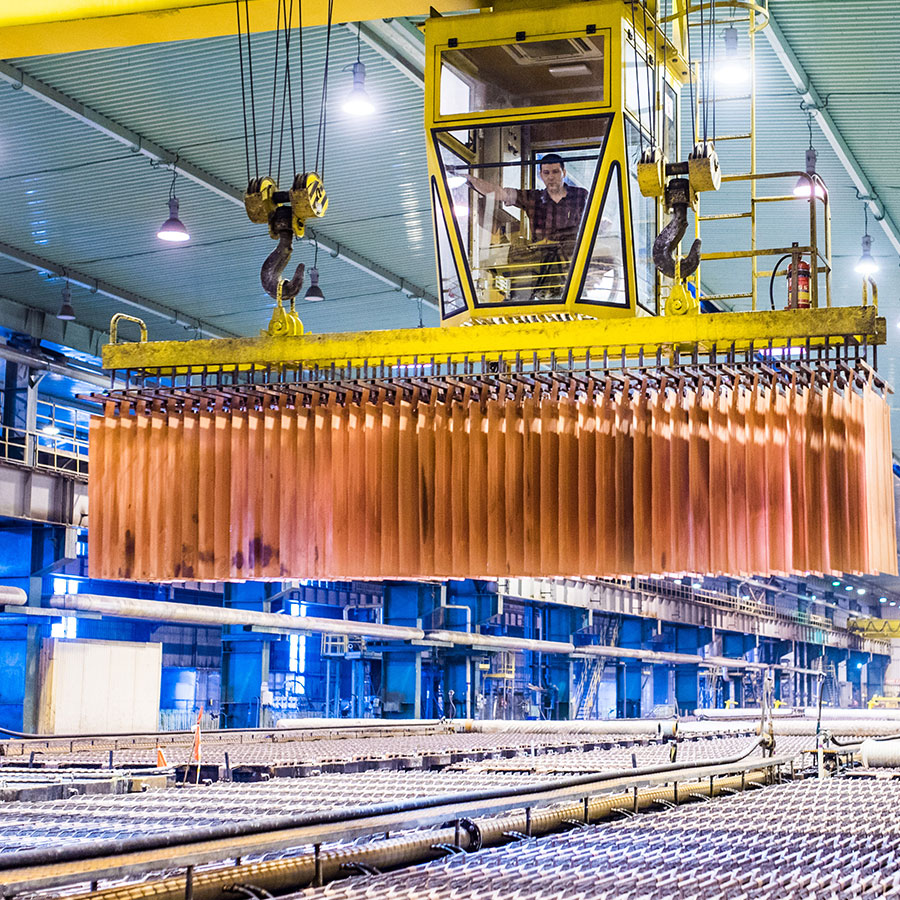

On behalf of the Management Board of KGHM Polska Miedź S.A. I hereby present you with the Annual Report of the Company and of the KGHM Polska Miedź Group for 2021.In 2021 KGHM celebrated its 60th jubilee as a company. We recalled the Company’s pioneers and the most important events in the history of the copper giant, unswervingly looking towards the future, and above all concentrating on our daily work and enhancing the efficiency of our company’s actions. An ambitious climate policy, the strategic treatment of energy transformation and very good production and financial results, mean that we have written new pages in KGHM’s history, of which we can be proud. It is with genuine satisfaction that I hereby present you with the results of the Company and of the KGHM Polska Miedź Group for 2021.

The future

is made of copper!

It is the output of the European nonferrous metals industry that makes energy transformation and the vision of a climate-neutral Europe possible.